HEAVY OIL OPERATION SYSTEM (HOOS)

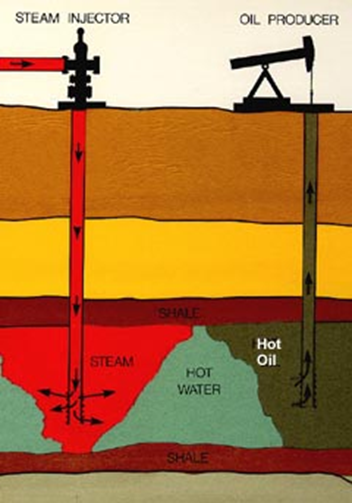

Conventional production

Steam is used to pressurise and heat heavy oil to allow pumping

Viscosity decreases with temperature

Steam injection requires expensive boilers or turbines and may not be available in all fields, which leads to: -High energy costs -Erratic production -Complex operations -Not always profitable

The HOOS Solution

HOOS technology reduces OPEX of heavy oil production:

-Reducing power usage by 50-90%.

-Virtually eliminating workover costs.

-Significantly increasing production time.

-Abruptly reducing water-cut.

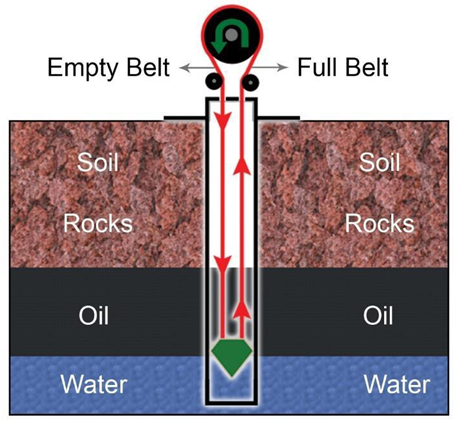

Innovative HOOS unit LIFTS oil with a continuous belt, rather than creating SUCTION with a pumping device

The aboveground head unit pulls the kevlar belt up coated in viscous oil

The unit strips the oil from the belt, measures the output and transfers oil for collection

HOOS technology allows heavy oil extraction without steam or other energy-intensive down-hole techniques

HOOS Unit

HOOS is an oil lifting technology focusing on medium and heavy oil reserves. In contrast with traditional technologies, it replaces the vertical pumping with vertical transportation.

HOOS is an oil lifting technology focusing on medium and heavy oil reserves. In contrast with traditional technologies, it replaces the vertical pumping with vertical transportation.

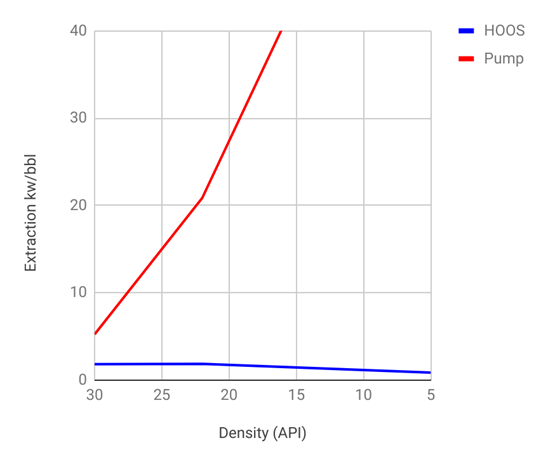

Conventional lift technology uses more energy than HOOS and gets more expensive as oil gets thicker and heavier due to efficiency losses in pumping

HOOS is more energy efficient overall than pumping, AND…

Because viscosity aids lift efficiency, HOOS technology uses LESS energy as oil gets heavier and thicker

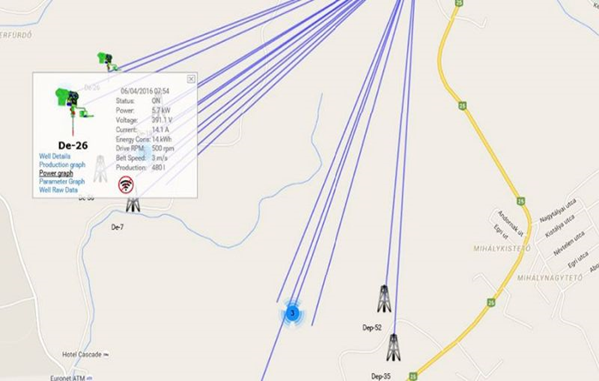

HOOS: cloud operability

Continuous monitoring includes instantaneous production, power consumption, belt speed & temperatures, through a secure VPN to a central cloud server

The cloud server summarizes HOOS unit operations: GIS positioning, contextual menus, operating calendar, intelligent schedules, workflows, alerts, production history and cost forecast

Measures production in real time

Proprietary Well Operating System monitors and records every parameter of the running equipment.

Proprietary Well Operating System monitors and records every parameter of the running equipment.

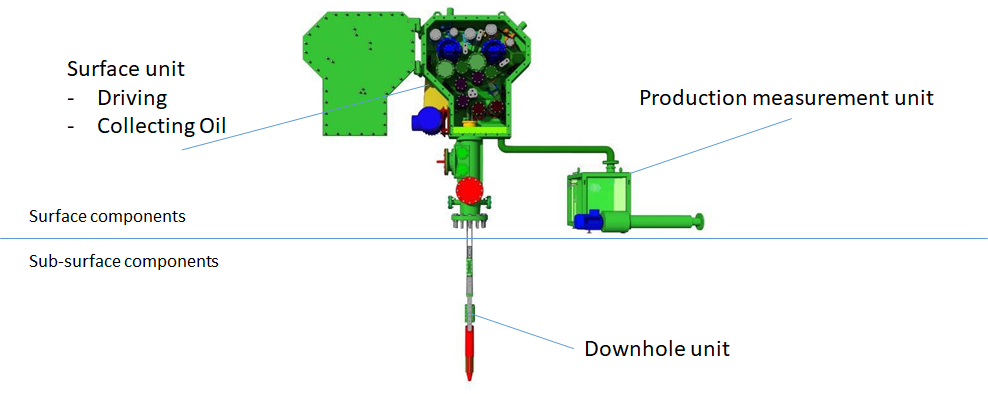

The surface unit is an assembly of different specialized systems:Efficient modular driving system, capable of generating more than 5 tons force, that is 5000m depth.

Metering system: instant production, energy consumption

Control system: fully featured IT operating system

Moebius system: single sided continuous belt

Oil collecting system: variable compression unit and air compressed blowing unit

Auto-status system: belt speed unit, pressure unit, temperature unit, proximity unit, video broadcasting unit

Belt anti-stick system to reduce down hole paraffin deposits Pressure prevention system, up to 160 bar

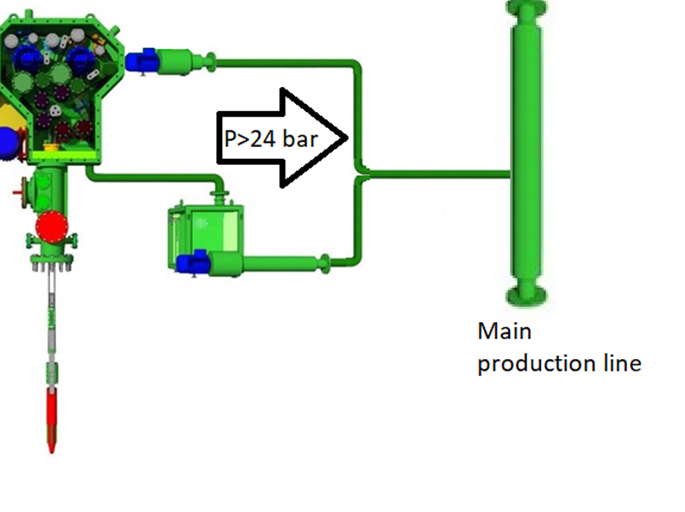

How gas is produced

HOOS is a natural separator of gas and oil.

The surface unit acts as an extension of the casing, therefore gas floats freely from the perforations to the surface and inside the surface unit, driven by the pressure. Then, on the right side of the surface unit there is a special flange (red bullet) where the gas can be collected and sent to the main line, flared or converted into power. Oil goes downwards to the metering unit, it is measured and the pushed forward to the tank or to the gathering park.

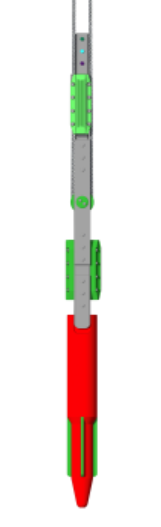

HOOS – Down-Hole Unit

Technology within down-hole unit:

Variable dimensions, to fit the casing

Modular design to alter unit weight

Heavy duty bearings

Anti-torsion system

Anti-seizing system, allowing slight vertical movement

Maintain optimal belt tension